Chain of Command

Commissioned by curator Brendan Cormier of the Victoria and Albert Museum for 'Values of Design,' published on the opening of the V&A Gallery in Shekou, China.

An Essay in Three Parts

1.

Hands up: who knows what skelp is? No, it’s not a variety of seaweed. Nor is it the skin stretched over your skull. It is the raw material from which tubular steel is made. Skelp is a thin, narrow sheet of metal that can be curled across its shorter dimension, and then heat welded along a straight seam. This produces a long tube, usually circular in cross-section.

Of course the story of tubular steel production doesn’t begin there - in fact, the story is quite a long one. I’ll try to summarize. Skelp is rolled from thicker ingots, which are produced in blast furnaces; what goes into the furnace is a mixture of different metals, depending on the alloy desired. In the case of steel, iron is the main ingredient. Usable iron comes out of the ground in the form of oxide ore. The most common type is hematite, named for the Greek word for blood, because it’s often red.

The single largest operating source of iron in the world is S11D, a mine in the Carajas mountains of Brazil. Its deposits contain over four billion tons of hematite. S11D is owned by Vale, the world’s largest iron-producing company; as of 2016 it is on track to invest almost $15 billion into the Carajas project. S11D is so big that its operations determine the price of iron ore on commodity markets. Recent reports suggest that, thanks to efficient “truckless” operations there, involving extensive systems of belts for transporting the minerals, as well as a weak Brazilian currency, the cost of iron ore may dip below $10 per ton.

The story continues further. In addition to its operations at Carajas, Vale is a 50% owner of the Samarco mine in Mariana, Brazil. On 5 November 2015, a tailings dam at the Samarco facility failed, leading the deaths of at least 17 people. There was also extensive environmental damage to the river basin, and to communities living downstream and along the nearby Atlantic coastline. [Fig 1] The cause of this incident, which has been called the worst environmental disaster in Brazil’s history, is still under investigation.

These facts are all available online, but I would guess that most people who come into contact with tubular steel chairs are completely unaware of them. Designers, curators and consumers alike are more likely to know about Marcel Breuer, the Hungarian-born genius who, supposedly inspired by bicycle construction, pioneered the use of this industrial material at the Bauhaus. His work in tubular steel began with the Wassily (1925), which has the wide stance and arms of a leather club chair, and moved on to other forms including the snappy, cantilevered Cesca (1928). [Fig 2] Breuer’s designs immediately became icons of modernism, and though they were slow to enter mass production, became ubiquitous after the Second World War. They are still manufactured in licensed versions by Knoll ($2500 for the standard Wassily, $1300 for the Cesca). There are also innumerable knockoffs. You can get a Cesca lookalike for $109 at restaurantfurniturewarehouse.com or any number of other websites.

Designers typically regard tubular steel as one of many “raw materials” at their disposal. In fact, it is highly processed stuff, which comes to the furniture factory only after many stages of production. All along this commodity chain there is relevant human action, much of which also deserves to be recognized as design. Mine construction, mineral extraction, mill operation, transport, and of course the specifications of the tubular steel itself, all involve the complex interaction of professionals. Many of them are thinking as designers, in the fundamental sense that they are shaping materiality according to plan. True, much of their work might better be described as “engineering,” in that it lacks the aesthetic component that makers Breuer’s chairs so enduring. The dividing line between aesthetics and functionality is notoriously blurry, however. (Breuer and his colleagues at the Bauhaus, as it happens, were among those who initiated the blurring.) An expansive definition of design, then, should take in all the strategic material interventions that occur along the commodity chain.

We might initially think of Breuer as the sole designer, or author, of his chairs. But once our range of awareness broadens to encompass the whole lifecycle of their materiality, we realize that many sequential moments of design have gone into their making. The iron in it was mined and refined, moved and manipulated, by many people. Equally, once the chair has been manufactured, it will almost certainly be subjected to further design agency. This could be through an act of contextualization (in a store by a retailer, or in a home by an interior decorator) orperhaps through subsequent material alteration. At each stage in the process, design expertise is applied to achieve the desired result.

This model of design, in which it is seen as a moment of decisive and intended change within an otherwise persistent material condition, also helps us to see the ethical implications of design more clearly. Consider the following passage, from the November 1896 issue of a magazine entitled The Practical Engineer:

In the early days of gas lighting, gun barrels were employed for the conveyance of the gas. In 1815, William Murdoch, the founder of gas lighting, in setting down an installation at the Soho Works, near Birmingham, employed old musket barrels screwed together as the means of conveying the gas throughout the works. The close of the long European war had thrown an abundance of such barrels on the market, and hence they were undoubtedly the most economical form of tubing available for the purpose. Someone has been unkind enough to observe that in modern times Murdoch’s plan has been reversed, for instead of making gas pipes from gun barrels, it is said that gun barrels for the African and other remote markets are sometimes made from gas pipes.

The material domain has its own commonalities, which we may or may not choose to exploit. Breuer chairs, gas lines, and gun barrels are all made of the same stuff, more or less. How we decide to make and deploy materials like steel – to sit, to illuminate a factory, to pursue armed conflict in the cause of imperialism – is among other things a design question. The transformation of rifle barrels into gas pipes, and vice versa, is an unusually stark demonstration of this principle. But a $2500 Wassily chair pulled out of a Brazilian mountainside is ultimately part of the same pattern.

2.

Hands up: who’s heard of Brooks Stevens? Not a household name, perhaps, but I once curated an exhibition about him. The subtitle of the show was “how Brooks Stevens shaped your world,” with some justification. His lack of fame is partly due to the fact that he spent his life and career in Milwaukee, Wisconsin – not usually considered a center for design thinking – and partly because he concentrated his energies on relatively anonymous industrial products like machine tools and outboard motors. In doing so, however, he played a substantive role in shaping postwar American material culture. Along the way, he created some of the most successful brand identities of that landscape, including the first civilian vehicles for Jeep, the Miller Brewing logo, and that beloved piece of Americana, the Oscar Mayer Wienermobile.

Like Breuer and the other progressives at the Bauhaus, Stevens was perfectly aware of the political implications of his profession. The difference is that he was emphatically right wing. During the 1950s, in the heart of his career, he advocated vociferously for the role of design in strengthening America’s economy, and hence its position in the Cold War. He popularized the term “planned obsolescence” as a key objective of the industrial designer: to make the customer want something “a little newer, a little better, a little sooner than is necessary.” Stevens was completely insensible to the environmental consequences of this position, and certainly did not take an interest in the politics of steel, or the other materials that went into the objects he styled. He was, however, highly attuned to the commercial role of design, and its future lifecycle: what happened once a rendering left the draftsman’s table, was adapted into an object, and sent out into the world.

Stevens is as good a case study as any in considering design’s materiality. So far, I have been addressing the designed object itself, the final product (though like the term “raw material,” the term “final product” is something of a misnomer). But the design process itself has a material basis. Whether through a sketch, blueprint or technical drawing, three-dimensional model, working prototype, digital rendering, or some other preparatory medium, a designed object almost always has a predecessor. The material qualities of this “pre-object” are often felt in the result.

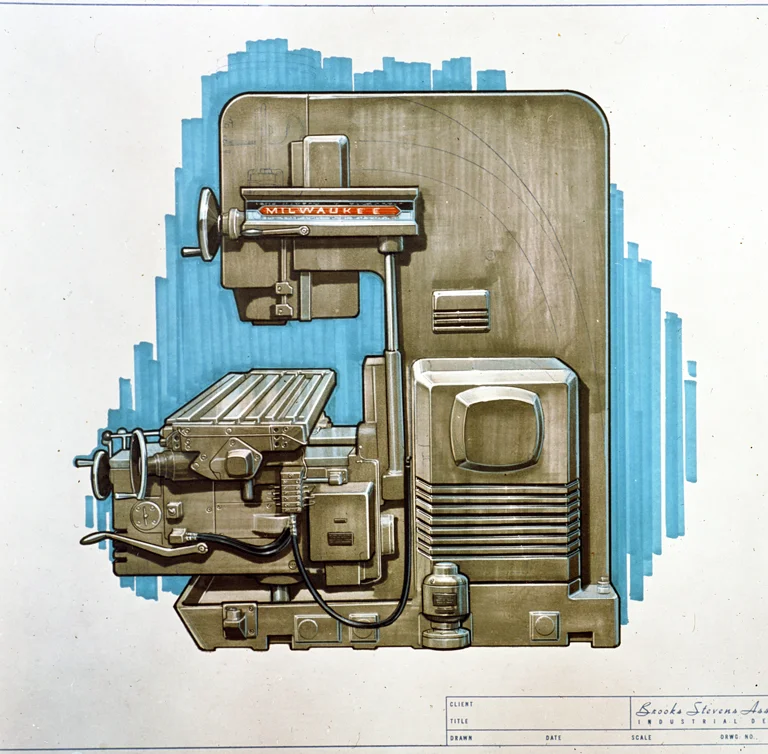

When I was studying Brooks Stevens’ work, a shift that particularly fascinated me was that from airbrush to felt-tipped marker. From the 1920s through the 1960s, he retained a specialized rendering artist in his studio. This man used pencil, fine pen, and airbrush to make very finished hand renderings, giving each drawing a curvaceous, pneumatic look. This was a common approach, and the choice ofmedium played an important and under-acknowledged role in the popularity of streamlining during these years. In the 1960s, however, there was a change. Autostylists in Detroit began to use blunt, felt-tipped markers in order to realize their renderings, and the draftsmen in Stevens’ office followed suit. This new drawing medium produced a look that one former Stevens staffer described to me as “chamfered,” with hard edges and choppy, boxy volumes. [Fig 3]

In the last twenty years, a similar but much more sweeping change has occurred in design, as digital techniques have displaced hand rendering. The advantages of this shift are many. First, the designer can create many iterations of a particular idea with relative ease, in order to adjust it or to provide optional variations to a client. Second, the object can be rendered as a three-dimensional virtual model, which can be rotated and evaluated from every angle before it is prototyped. Third, a digital sketch can be used for programming a tool like a router or a 3D printer – the rendering actually drives the making of the object.

These processes are all well understood by designers and have arguably played a role in expanding the reach of the profession – think of the tremendous impact of Apple, which has put design tools into the hands of everyday citizens, as part of a broader expansion of the digital domain in our lives. (Apple also relies on digital processes to shape its own products, producing an aesthetic result that is smoothed out, edgeless, oddly reminiscent of the work of 1930s.) Digitization has had another general effect, too, derived from a misplaced sense that the digital is, in some sense, not material at all. Partly because of the inoffensively fluid interfaces through which we encounter it, the digital seems like a frictionless domain – the ultimate streamlining. We even speak of “dematerializing” our lives, getting rid of our paper books and magazines and desk calendars in favor of a single information portal.

In actuality the digital is assertively material, and not only in the sense that it is powered by enormous servers, and handheld devices that are metal- and plastic-hungry. It also brings into being configurations of global exchange that are unprecedented in their reach and scale. One important, seemingly innocuous feature of digital renderings is the fact that they can be sent anywhere, in an instant. This greatly reduces the cost of doing business with distant manufacturers. 3D printing and other automated forming techniques make this feat of teleportation even more powerful. Face-to-face collaboration between the designer, the prototyper and the producer is no longer necessary. This convenience, more than any other single factor, has enabled designers to operate more globally than ever before – to have their ideas realized by strangers half a world away.

Companies seeking an optimal balance of quality and cheapness have seized uponthese tools. This has dramatically hastened the decline of the manufacturing base in Europe and America, and contributed to the expansion of the factory sector in Asia, Latin America and (to some extent) Africa. It is a redeployment of productive activities enormous in scale and pervasive in its political ramifications, arguably implicated in phenomena as disparate as uprisings in Bangladesh in 2015 (partly motivated by the appalling working conditions of the country’s four million garment workers), and the popularity of Donald Trump in America (partly motivated by perceptions that the working class has been betrayed). It may be difficult to accept that such dismaying political developments could be linked to design, but linked they are, as surely as a 1965 Ford Mustang is linked to a felt-tipped marker. The tools we use to shape our designs have an inbuilt material logic. As we have our way with those tools, intervening in our material environment through design, the tools can in turn have their way with us.

3.

I mentioned in the first section of this essay that ersatz Marcel Breuer chairs can be had for less than 10% of the cost of the authorized version. [Fig 4] The same can be said for almost any classic furniture design, so much so that an entire organization called “Be Original” has come into being to pursue legal action against offending manufacturers and retailers. At least in the case of furniture, there is the option of legal recourse. In other fields though, notably fashion, there is no intellectual property protection for design in the first place. As a result, knockoffs are the global norm. Most clothing, most handbags, are manufactured by companies who pay nothing for the designs they use.

As frustrating as this situation is for designers, the opposite phenomenon can be even worse. In recent years, conflict over intellectual property has become a stranglehold on certain areas of the economy, particularly in the United States. All patents limit entrepreneurship; that is the way patents work. But now patent holders are treating intellectual property as a profit model in its own right, laying claim to innovations that are very broadly framed, and then engaging in legal action in order to exact (one might better say extort) financial concessions from other companies. In many cases the patent holders are not even manufacturers, but so-called “patent trolls,” shell companies that derive their sole income from such lawsuits.

Patent offices are overwhelmed by the scale and technological complexity of this situation, and the government has only belatedly begun to address it through aggressive legislation. The economic damage caused by patent trolling is hard to calculate, but in the USA alone it is certainly on the order of billions per year, concentrated particularly in the software, pharmaceutical, and manufacturing sectors.

Given such abuses, and the less pernicious but certainly real chilling effect that all legitimate patents have on economic growth, many affiliated with the so-called “copyleft” movement have argued that intellectual property regimes are outdated, and must be comprehensively reformed. Even in the museum sector, a tiny corner within these debates, the issue is problematic. A large institution like the V&A spends a great deal of resource clearing and clarifying rights to images for use in books and exhibitions, including objects in its own collection. Often it is unclear who, if anyone, benefits from this time-consuming work.

Rights regimes may seem to be a non-material consideration (hence the term “intellectual,” as opposed to physical, property). But, as the example of patent trolling indicates, there are significant material consequences when these rules are enforced. Intellectual property is a powerful and sustainable form of capital, and whole industries shape themselves according to its dictates. China is a great example. In the 1990s, it achieved much of its economic momentum through black market production, simply ignoring the intellectual property claims of other countries. Now, however, it has recognized the limitations of this strategy: ersatz Gucci bags and the like may be profitable, but can only ever be a stage in the process of economic development. China is therefore engaged in an effort to change its international reputation as a knockoff specialist, investing hugely in design training.

Individual designers are also changing their approach to reflect intellectual property concerns. Leading schools like the Royal College of Art support young designers in securing patent protection for their ideas, and also encourage them to anticipate the illegitimate copying of their ideas: if you are certain to be knocked off anyway, you may as well try to control that process. Savvy designers now think of their ideas as cascading outwards, at decreasing levels of fidelity. The next frontier of advanced design thinking involves looking ahead to the innumerable unauthorized versions of a given idea, and altering the initial gesture accordingly. This may involve seeking to protect a design not through patents, but instead through dependency on specific, complex materials, which cannot be easily replicated. Conversely, some designers want their work to be knocked off. They create objects that are specifically meant to proliferate across the globe in rough approximations, in order to achieve positive social change.

Such are the new frontiers for materiality in design. We must unlearn longstanding habits in which materials are considered as “raw” or neutral. Nor can we understand “finished” design objects as autonomous and isolated, as they are often presented in museums, magazines and books. Instead, we should think of each act of design as a link in the commodity chain. This conception of the profession may make a designer feel less in control, more at the mercy of malevolent global forces.But the commodity chain extends in both directions. Acts of design ripple both backwards and forwards along it, through extended feedback loops. The more designers can understand and accept these material consequences, the more effective their designs will be.

Fig 1

Fig 2 - Breuer's Cesca chair, as currently offered by Knoll

Fig 3 - Brooks Stevens Office, felt-tip rendering for the Milwaukee-Matic, machine tool, n.d.

Fig 4 - Baxton Studio version of Marcel Breuer's Wassily chair; cited by Be Original Americas as unlicensed